Month: November 2023

Dampers of all types

Expansion joints Fabric & Metal

Expansion joints, whether fabric or metal, compensate for longitudinal expansion of the pipe or channel in all three directions and effectively interrupt vibrations. We supply compensators for the following industries:

- Fossil fueled Power Plants

- Gas Turbine Power Plants

- Chemical and Petrochemical Plants

- Steel Mills

- Cement Mills

Air intake system

Silenser

We supply a complete range of silencers for diesel and natural gas engines for installations from small to large, as well as all the necessary accessories. We supply custom inlet and exhaust silencers for gas turbine application.

We design silencers with an attenuation range of LP 30 to 60 dB.

Silencers can be absorptive, resonant or reactive, and in most cases a combination of these. Acoustic and velocity/pressure drop calculations for each design should be performed in parallel to obtain the most optimized result.

Heat recovery steam generator (HRSG)

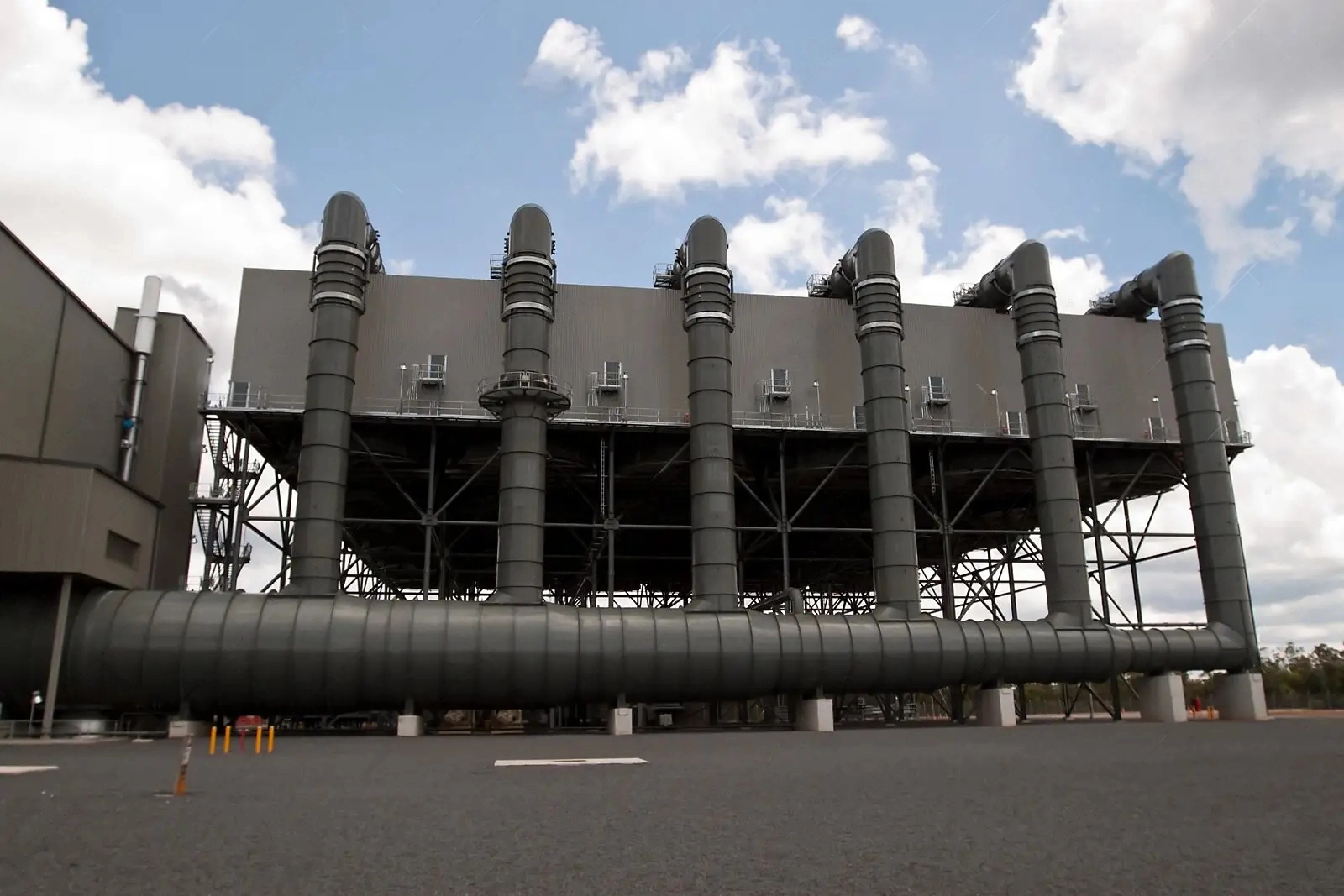

Air Cooled Condenser

Air-cooled condensers (ACCs) are heat exchange devices used in various industries, particularly in the power generation sector. They play a crucial role in power plants, especially in steam-driven power stations. ACCs are employed to cool and condense the hot steam exiting the turbines, transforming it back into liquid water. This condensation process is essential for the efficient operation of steam-driven power plants, as it allows for the reuse of water and maintains a high level of the system’s thermal efficiency.

Tube Heat Exchangers

Tubular heat exchangers are devices used for heat transfer between two fluids or gases flowing through a system of tubes. In the energy sector, they are utilized for various purposes, including dissipating heat from thermal generators and reactors at power plants, generating steam for turbines, heating or cooling turbines, and in solar thermal systems for collecting and transmitting heat from the sun to thermal systems

Plate Heat Exchangers

Plate heat exchangers are compact devices used for efficient heat transfer between two fluids. They consist of plates with fins or channels that provide a large surface area for heat exchange. The fluids requiring heat exchange are pumped through the space between these plates, and heat is transferred through the plate walls from one fluid to the other.

Plate heat exchangers are known for their efficiency, versatility, and ease of maintenance, making them widely used in areas such as ventilation and air conditioning, industrial processes, cooling, and renewable energy systems.

ReBuild Ukraine 2023

We are honored to share our excitement about our visit to the ReBuild Ukraine 2023 exhibition in Warsaw, which took place on 14-15 November. We had the privilege of engaging with representatives from various sectors, listening to their ideas and thoughts on crucial recovery issues, and sharing our own experiences and knowledge.

Our team is impressed not only by the diversity of initiatives and projects but also by the warmth and enthusiasm of the participants working towards the improvement of Ukraine’s economy, infrastructure, education, and many other aspects of life. We are confident that only together can we achieve significant changes and support the sustainable growth of Ukraine.