Category: Без рубрики(Eng)

Memorandum with Sievierodonetsk community

A memorandum was signed with a Dutch company to restore the energy sector in the Sievierodonetsk community.

It is noted that on 9 January, a memorandum of cooperation was signed by Oleksandr Stryuk, head of the Sievierodonetsk MVA of the Sievierodonetsk district, and Yura FORTI, managing director of UGENIA B.V.

“The purpose of this cooperation is to establish effective cooperation to restore the territory of the Sievierodonetsk community in the energy sector, which has suffered and is suffering the terrible consequences of military aggression by the Russian Federation,” the statement said.

It is noted that this memorandum is a continuation of cooperation with international partners in the framework of the participation of the Sievierodonetsk community for the second time in the International Exhibition and Conference ReBuild Ukraine, which took place on 14-15 November 2023 in Warsaw.

It is also noted that UGENIA B.V. has extensive experience in the international energy sector and is ready to act as an intermediary between the Sievierodonetsk City Military Administration and potential international suppliers of the necessary equipment to restore the electricity and heat sector of the Sievierodonetsk community.

“The Dutch company is ready to assist in the search for international investors to cover the financial costs associated with the purchase of the necessary equipment, its transportation to the destination and the initial commissioning of this equipment,” the Sievierodonetsk MCA said.

Dampers of all types

Air intake system

Heat recovery steam generator (HRSG)

Air Cooled Condenser

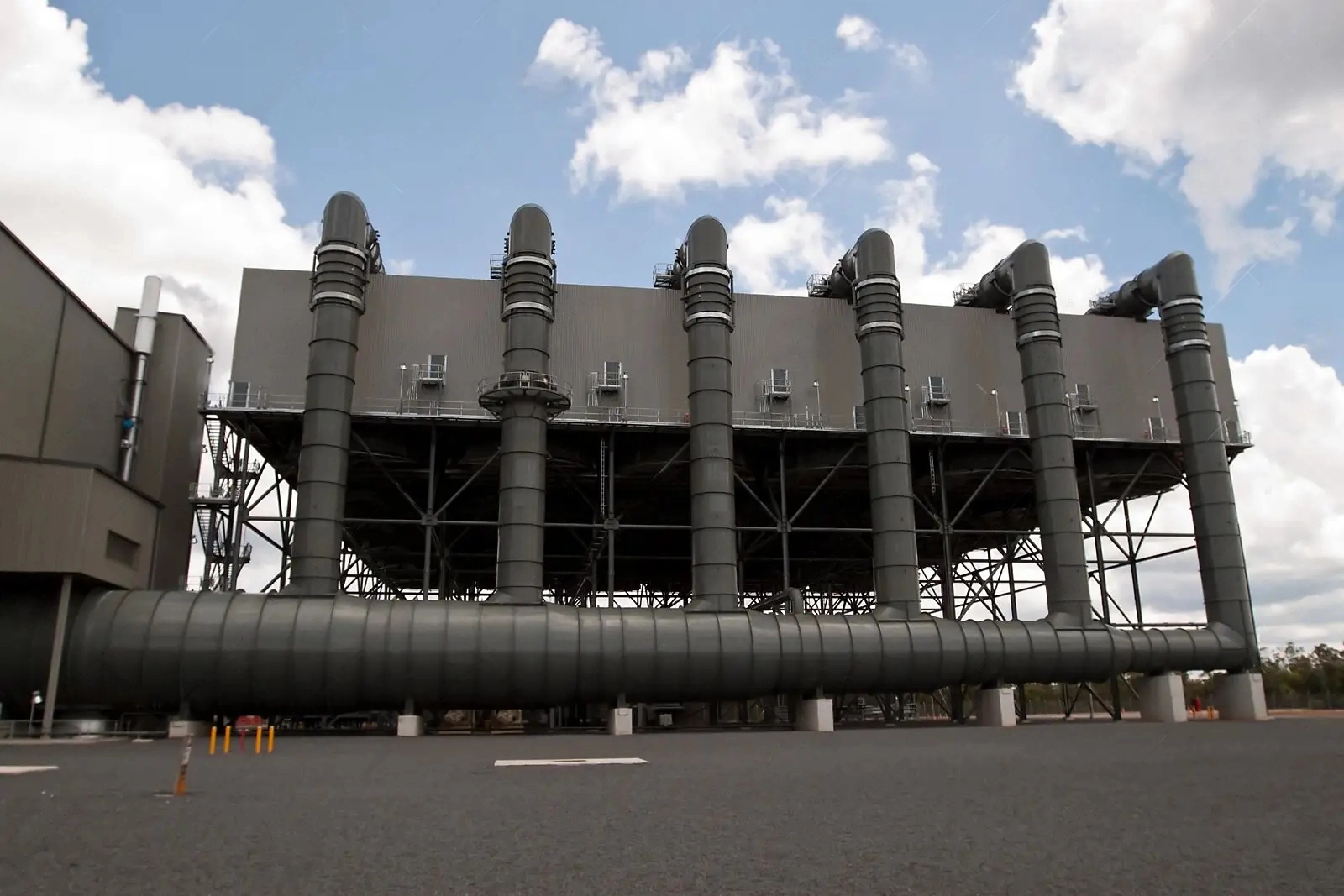

Air-cooled condensers (ACCs) are heat exchange devices used in various industries, particularly in the power generation sector. They play a crucial role in power plants, especially in steam-driven power stations. ACCs are employed to cool and condense the hot steam exiting the turbines, transforming it back into liquid water. This condensation process is essential for the efficient operation of steam-driven power plants, as it allows for the reuse of water and maintains a high level of the system’s thermal efficiency.

Tube Heat Exchangers

Tubular heat exchangers are devices used for heat transfer between two fluids or gases flowing through a system of tubes. In the energy sector, they are utilized for various purposes, including dissipating heat from thermal generators and reactors at power plants, generating steam for turbines, heating or cooling turbines, and in solar thermal systems for collecting and transmitting heat from the sun to thermal systems

Plate Heat Exchangers

Plate heat exchangers are compact devices used for efficient heat transfer between two fluids. They consist of plates with fins or channels that provide a large surface area for heat exchange. The fluids requiring heat exchange are pumped through the space between these plates, and heat is transferred through the plate walls from one fluid to the other.

Plate heat exchangers are known for their efficiency, versatility, and ease of maintenance, making them widely used in areas such as ventilation and air conditioning, industrial processes, cooling, and renewable energy systems.

Air- and Exhaust Systems

Heat exchangers

The process of heat exchange plays an important role in various engineering systems, and heat exchangers serve as a key element in this process. A heat exchanger is a device designed to transfer heat between two media at different temperatures. They are widely used in industry, heating, ventilation, air conditioning, chemical industry, energy and other industries.

Materials

Power plants play a critical role in supplying electricity to our cities and industrial enterprises. To operate reliably and efficiently, they require high-quality materials and components. The use of high-quality materials and components is a key factor in ensuring the reliable and efficient operation of power plants. The right choice of power cables, thermal insulation materials, exhaust systems, compensators, pumps and valves minimizes the risk of accidents, increases energy efficiency and reduces operating costs.